Nikoopak naghshe jahan Company established with the aim of achieving technical knowledge and production of special additives for using in detergent powder.This company, by advantaging a powerful organized research and development unit and well-equipped laboratory, managed to domesticate the technical knowledge of production of intercalated activated bentonite granules with the trademark “Softstar ® ”.

Access to high quality raw materials in addition to specific processing, exclusive registered formulation, high-tech equipment and appropriate investment provide a significant sustainable competitive advantage rather than European products. Diligence communication with research teams of consumers in one side and production according to market needs on the other hand, is the base of Nikoopak production team to achieve the aim of producing in the highest quality and increase the standard levels of detergent powder production in Iran. We have tried to repute Nikoopak name as a knowledge-based high quality producer with an ongoing scientific-trading relationship with customers.

What is Softstar ® ?

Bentonite-based fabric softener granules

Softstar® is Bentonite-based fabric softener granules (intercalated nanoclay) that formulated as a specific additive to detergent powders. Its nano layer structure provides several different unique properties which enhance detergent powder performance and its quality as well as being economic.

Softstar® (Processed bentonite granules) key benefits in detergent powder

- Increasing performance and efficiency

- Decreasing the builders percentage

- Possibility of producing softening–through–the wash detergent powder (2 in 1)

- Enabling easy ironing property

- Feeling of fabrics Softness due to increasing rewet (water absorbency) and static control.

- Preventing soil re-deposition on fabrics

- Protecting fibers and their color

- Decreasing the harsh of washing

- Decreasing detergent powder ash

- Enhancing of zeolite percentage in formulation

- Increasing production line capacity due to using as a post–add production

- Having compatibility with other components of detergent powder

- Reducing environmental concerns on waste water

Softstar® and Detergent powder production

Cationic surfactants, these days, are common chemicals which are used as fabric softener in a separate laundry step, in rinsing step, because they are incompatible with anionic components of the detergent powder formulation.

Softstar is formulated as an efficient additive in order to produce 2 in 1 detergent powder. According to ASTM standard D 5237-14, tested in Nikoo pak laboratory, washing towel fabrics and cotton cloths with 15% Soft star contained detergent powder for 10 times provide a significant softening effect than control group fabrics. Remarkable whiteness of Soft star in comparison with similar products makes it possible for manufacturer to increase Soft star in formula upper than 8%. Another significant benefit of adding Soft star in detergent powder is that it has compatibility with all other components so that washing process and softening steps can be combined to one user-friendly cost-effective short step. On the other hand, bentonite as a safe natural mineral reduces environmental concerns.

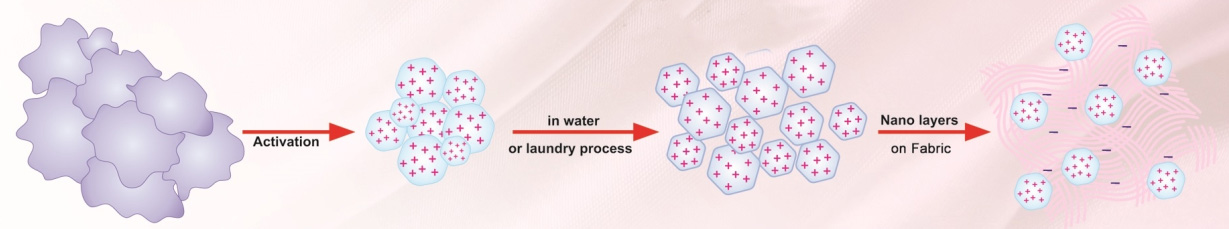

Softstar® in washing process

Bentonite as a key component of Softstar is a layered Aluminum silicate that its fabric softening effect stems in its ability to form a protective nanolayer on the textile fibers. As soon as bentonite encountering water the layers separate to form positively charged invisible nanolayer which adsorbed by negatively-charged fabrics. These nanolayers settled between the fabric yarns so decrease the friction between them and provide a total pleasure softening feeling. On the other hand, the soils that may occur during wearing the clothes will settle on the nanolayer instead of the yarns so protect the yarns from spoiling. In the next washing, all the dirt and soil which settled on the nanolayer separate from the clean fabric and a new nanolayer from the Softstar contained powder replaced with. Thus, fabric is protected by its color, dye and harsh. On other hand, Softstar prevents ashes of DP to settle directly on the top of the fabric, so decrease the total ash.

Softstar® in detergent powder formulation

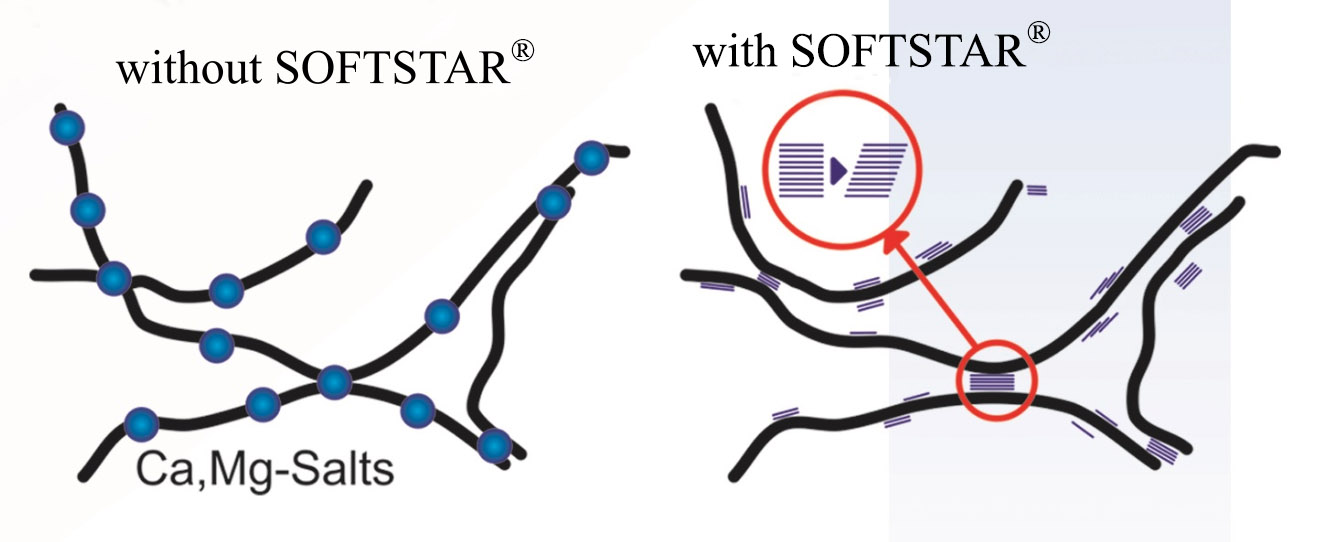

Soft star as a new generation of detergent powder additives provide a variety of benefits for manufacturers of detergent powder like reducing phosphates percentage as it provides a little amount of ion exchange property, increasing zeolite, increasing production line capacity as well as product stability in humid climate. Ion exchange capacity of bentonite lead to attraction of hard elements of water included calcium and magnesium so manufactures can replace Softstar with some portions of builders in their formulation that deal to price decreasing. Today, on the other hand, producers prefer to replace zeolite by phosphates because of phosphate environmental issues. But zeolite precipitation on fabrics and increasing ash content put the powder out of standard. By adding Softstar these problems solved as it prevents total precipitation followed ash content reduction. As Softstar is used as a post-add product, it increases the detergent powder production line capacity that is very economic for manufacturers. In humid climate, Softstar traps excess humid in the atmosphere so prevent coagulation of detergent powder and increase its free flow. In sum, it totally increase performance and efficiency of the powder.

The influence of Softstar® on the washed cloths

Organic fabric softeners are in use in detergent powder from many years ago but they reduce wettability property of the fabric that cause not to pass standard (ASTM D 5237-14) as well as not being compatible with the other components as they are cationic chemicals. Softstar increase the wettability so user feel a softer fabric. Nanolayers of bentonite settle between yards so it reduce friction and ease ironing of fabrics and cause more stability on the color of them as well as preventing participation of hard elements on the fabrics. Other benefits of bentonite nanolayers settlement on the yarns is preventing incrustation and the electrostatic charge of fabrics.

نیکو پاک نقش جهان

نیکو پاک نقش جهان